Description

Portability and excellent arc performance make the

XMT family the most popular in the industry.

With multiprocess capabilities and features like Auto-Line, the XMT 350 is

portable and versatile for applications from jobsites to the factory floor.

Miller XMT 350 is a multiprocess power source for petrochemical, construction, shipbuilding and other industrial applications.

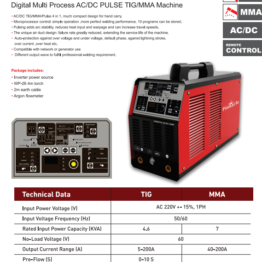

The Miller XMT 350 DC CC/CV power source features multiprocess selection. By simply changing accessories, an operator can select between the MMA, MIG, FCAW, MCAW and TIG processes. Auto-line 208 – 575 VAC +-10%, 50/60 Hz. Rated at 350 A, 60% duty cycle.

APPLICATIONS:

Applications include petrochemical, construction, shipbuilding, railroad, truck/trailer manufacturing, fabrication and power generation plants.

FEATURES & BENEFITS:

Miller XMT 350 CC/CV Power Source – Rugged, Versatile Multi-Process Welding Inverter

The Miller XMT 350 CC/CV is an industry-leading multi-process welding power source that delivers superior arc performance and versatility in heavy-duty environments. Built with Miller’s inverter technology, it provides a compact, lightweight solution that doesn’t compromise power or reliability.

This unit supports CC (constant current) and CV (constant voltage) output modes, enabling high-quality Stick, MIG, TIG, and Flux-Cored welding. Its intuitive front panel and advanced arc control features make it ideal for use across construction, shipbuilding, fabrication, and maintenance industries.

Engineered for durability, the XMT 350 features Wind Tunnel Technology™ to protect internal components from contaminants, and Fan-On-Demand™ cooling that only runs when needed—reducing noise and power consumption.

Key Features:

-

🔧 Processes: Stick, MIG, TIG, Flux-Cored

-

⚡ Output Modes: Constant Current (CC) & Constant Voltage (CV)

-

🧠 Advanced Arc Control: Smooth, stable arcs with customizable parameters

-

🌬️ Fan-On-Demand™: Reduces energy usage and contaminants

-

🛡️ Wind Tunnel Technology™: Keeps dust and debris out of sensitive components

-

💼 Portable Design: Compact and lightweight for jobsite mobility

-

🔗 Compatible With: SuitCase wire feeders, TIG modules, remote controls, and more

Specifications:

-

Input Power: 3-phase, 400V

-

Output Range: 5 – 425 Amps

-

Duty Cycle: 100% @ 300A (400V 3-Phase)

-

Dimensions: Approx. 394mm x 318mm x 546mm

-

Weight: ~38 kg

-

Applications: Industrial fabrication, shipyards, structural steel, field maintenance