Description

The Harris H-19-2E precision mixer is a high-quality equal pressure mixer designed for use with Harris welding and cutting torch handles. This robust and efficient tool ensures perfect gas blending for oxy-fuel applications, making it ideal for both cutting and welding tasks. Whether you’re working with acetylene, LPG, or propane, this mixer provides consistent, clean flame control.

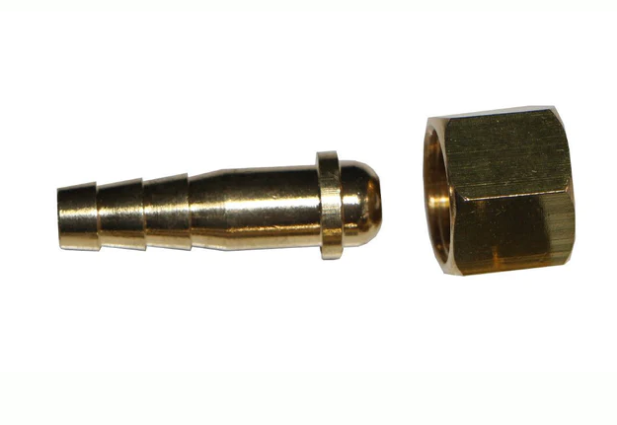

Built with durable brass construction, the Harris H-19-2E precision mixer resists corrosion and wear, even in tough workshop environments. It fits directly onto Harris-style torch handles and accepts compatible tips, creating a secure and leak-resistant connection. This makes it a must-have for professionals who need reliable, repeatable performance on the job.

Because it uses the equal pressure principle, this mixer helps maintain consistent flame characteristics even when gas pressures fluctuate. That means your welds and cuts stay smooth, efficient, and safe throughout the work process.

Ideal for:

-

Welding and cutting with equal pressure systems

-

Use with oxygen + acetylene or oxygen + LPG setups

-

Harris-style torch handles and compatible tips

-

Industrial and commercial welding workshops

Key Features:

-

Equal pressure mixer for consistent flame output

-

Rugged brass body for durability and longevity

-

Easy connection to Harris torch handles

-

Compatible with a range of welding and cutting tips

-

Supports professional-quality welds and clean cuts

Explore more options in our full Gas Equipment category (internal link). For further technical details, you can review the Harris Products Equal Pressure Mixers Overview (external link).

If you’re searching for accuracy, durability, and flame control, the Harris H-19-2E precision mixer delivers exactly what professionals need. It’s a reliable tool for any serious welding and cutting setup.