Description

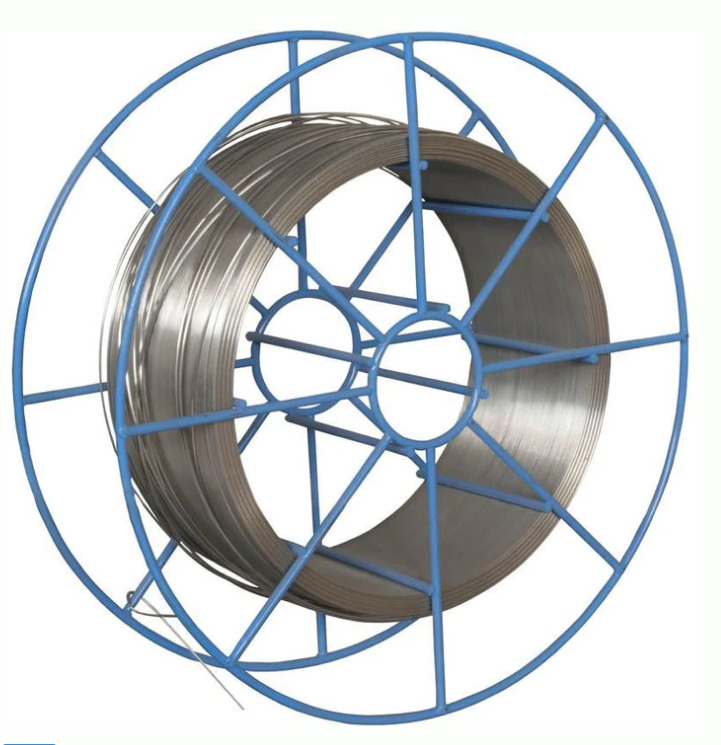

🔧 ERCuNi5Al9 MIG Wire 1.2mm – 5kg Spool for Copper-Nickel Welding

The ERCuNi5Al9 MIG wire (1.2mm diameter) is specifically engineered for welding copper-nickel alloys used in marine, chemical, and power generation industries. Supplied on a 5kg spool, this wire provides smooth feedability, arc stability, and excellent resistance to corrosion and seawater exposure.

This alloy contains approximately 70% copper, 30% nickel, and small amounts of aluminum, iron, and manganese—designed to deliver strong, ductile welds in critical environments. It’s commonly used for joining 70/30 CuNi base metals and overlays on steel for corrosion protection.

💪 Applications of ERCuNi5Al9 MIG Wire

The ERCuNi5Al9 MIG wire is ideal for applications where corrosion resistance and metallurgical compatibility are critical. Common uses include:

-

Heat exchangers and condensers

-

Marine piping systems and shipbuilding

-

Offshore oil and gas platforms

-

Power plant tubing and water cooling lines

-

Cladding and surfacing on steel exposed to saltwater

Its excellent arc characteristics reduce spatter, resulting in cleaner welds and reduced post-weld cleanup. The deposited metal resists pitting and stress corrosion cracking, making it a dependable solution for high-performance environments.

⚙️ Performance & Welding Recommendations

Use this wire with Argon or Argon/Helium shielding gas mixtures to achieve a stable arc and good penetration. Recommended current for 1.2mm diameter ranges from 160–220 A, depending on position and material thickness.

Ensure surfaces are clean and free from oil or oxidation. For detailed welding tips and amperage settings, visit our welding parameters guide.

📚 Expert Resources & Support

At Fourie Welding & Tool, we supply premium welding products backed by expert support. Learn more about copper-nickel welding procedures at the American Welding Society: aws.org.

When performance and corrosion resistance matter, trust ERCuNi5Al9 MIG wire to deliver reliable results in harsh environments.