Description

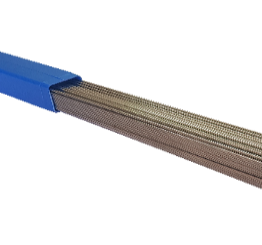

The ER410NiMo 2.0mm TIG Wire 5kg is a high-alloy stainless steel TIG filler rod designed for welding martensitic stainless steels that require superior strength, impact resistance, and corrosion resistance. It contains chromium, nickel, and molybdenum, which together provide a strong, tough weld deposit with excellent mechanical properties—even in harsh environments.

Welders often use ER410NiMo TIG wire for components such as turbine blades, hydraulic shafts, valve seats, and high-strength tools. The addition of nickel improves toughness, while molybdenum increases corrosion resistance—especially in applications exposed to water, steam, and chemicals. This makes the wire ideal for energy, petrochemical, and marine industries.

With a diameter of 2.0mm, the wire allows precise arc control and smooth bead formation. It delivers a stable arc and minimal spatter, resulting in clean, high-integrity welds. Whether you’re fabricating critical components or rebuilding worn parts, ER410NiMo TIG wire ensures both strength and reliability.

To achieve the best results, use DC+ polarity and ensure the base metal is clean. Preheating and post-weld heat treatment are often recommended to reduce the risk of cracking and to achieve the desired hardness. The 5kg spool provides enough filler for moderate to large jobs without being cumbersome.

This wire is especially useful when working on stainless steels that must endure mechanical stress and corrosive conditions. It offers an advantage over standard ER410 because of its superior toughness and durability.

At Fourie Welding & Tool, we supply premium welding consumables that support the demanding work of South African welders and fabricators.

For technical specifications and application details, visit Lincoln Electric’s stainless filler metal guide.